Capability

Capability shows at a glance how the system's various inspections are performing according to known (labeled) inspection results.

Overview

The total system capability can be seen immediately and can be further discriminated by inspection result dates.

Definitions

True Positive: A passing part that is expected to pass.

True Negative: A failing part that is expected to fail.

False Positive: A passing part that is expected to fail.

False Negative: A failing part that is expected to pass.

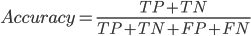

Accuracy

Accuracy in this case is the raw measure of how well the inspection performed. It is calculated as the ratio between the True results and all the results as shown below.

where TP = True positive; FP = False positive; TN = True negative; FN = False negative

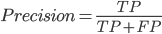

Precision

Precision is the measure of how correct the positive identifications were.

where TP = True positive; FP = False positive;

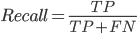

Recall

Recall is the proportion of actual positive results were successfully identified.

where TP = True positive; FN = False negative

F-Score

F-Score is the harmonic mean of precision and recall and is used as a measure of accuracy only considering positive results.

where TP = True positive; FP = False positive; FN = False negative

Per Inspection

Each inspection's individual capability can be browsed for the same statistics by clicking on the inspection cards at the bottom of the page.

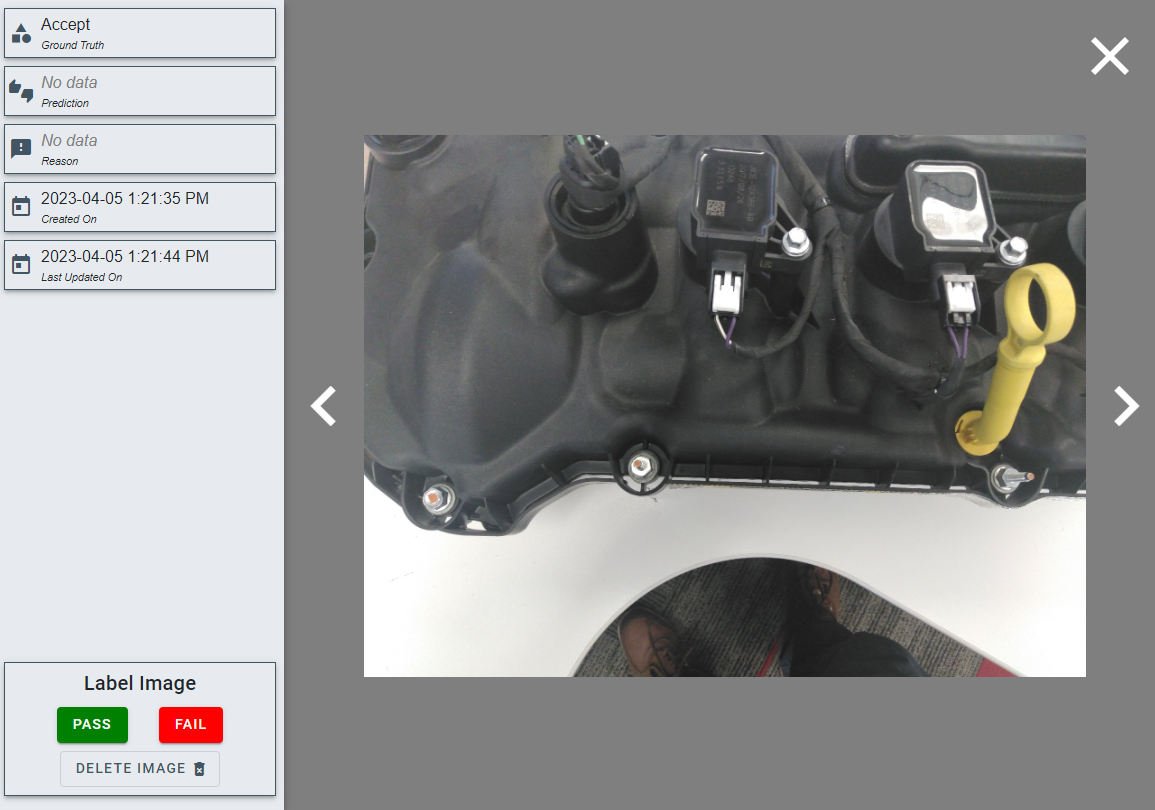

Operation

There are two ways of classifying images with ground truths in MVS. The first is to classify the images in the same way that the challenge process images are classified in the system.

The other way is to enable the feedback mode on the inspection point so that operators can add ground truths during the regular process.